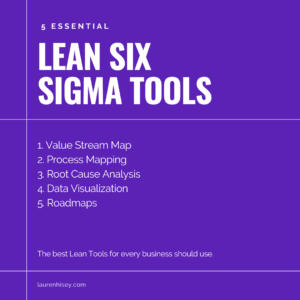

Five Essential Lean Six Sigma Tools every business should use

🛠 The Continuous Improvement Toolset encompasses many tools that can be hard to pick, especially if some provide similar outputs. But there are five essential Lean Sigma Tools every business should use

🛠I always tell my students to pick the right tool for their situation.

🛠I also know from working with clients that I use specific tools with almost every engagement.

💡 Here are the top five Lean Six Sigma tools that every business should consider using:

✅ Value Stream Mapping (VSM): A map that visualizes the flow of material, cycle times, and value add and non-value of the e2e process. My friend Karen Martin describes a VSM as the overall end-to-end flow map.

✅ Process Mapping: From the high-level SIPOC (Supplier, Inputs, Process, Outputs, Customers) to visually represent the key elements of the process to a detailed process map (ex, cross-functional maps) to see each detailed step in the process. It helps teams understand the flow of activities, identify wastes, and improve scope.

✅ Root Cause Analysis (RCA): RCA is a problem-solving tool that helps identify the causes of the issues within a process. The following RCA tools can be used, 5 Whys, Fishbone Diagram, Pareto Chart, FMEA, etc.

✅ Data Visualization: There are various ways to represent data. I always like to say that data takes the gut feeling we get through RCA and provides some concrete math and information to validate what is being felt and point you in the right direction. Without data, you are not able to validate the crucial issues, and you are not able to tell the story. You can use graphs, Statistical Process Control Charts, hypothesis tests, etc., to help tell the story. Especially the before and after pictures.

✅ Roadmaps: While a project roadmap may not seem significant to some, it is essential because it helps guide you down the right path. Roadmaps can be as big as a Future State Roadmap to as small as Project Roadmap or PDCA Roadmap. These maps guide the last, current, and future steps that can be adjusted.

💡Implementing tools effectively can help operational excellence, employee satisfaction, and greater customer satisfaction.

👉 What CI tools have you used?

👉What is your favorite CI tool?

👉If you want to learn about the CI toolset, let’s schedule a time to talk.

Leave a Reply