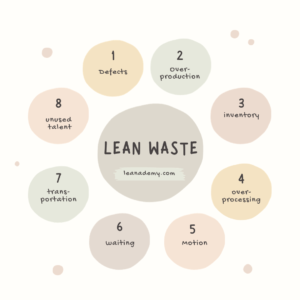

Lean Wastes

- Defects

- Overproduction

- Inventory

- Overprocessing

- Motion

- Waiting

- Transportation

- Unused Talent

Unearthing the Lean Wastes

In a quest for operational excellence, identifying the principles of Lean Six Sigma has emerged as a beacon of efficiency. Part of these principles is unearthing the Lean Wastes to eliminate them, streamline processes, and enhance productivity.

Let’s explore the eight types of Lean Wastes, illuminating areas where organizations can focus their efforts to unlock untapped potential.

Eight Lean Wastes

- Defects: Quality issues or errors can lead to rework, scrap, and dissatisfied customers. Lean encourages a proactive approach to quality, seeking to identify and address the root causes of defects.

- Overproduction: Producing more than is needed can lead to excess inventory, increased storage costs, and potential quality issues. Lean seeks to align production with customer demand, reducing unnecessary surplus.

- Inventory: Idle inventory ties up valuable resources and capital. Lean encourages a ‘just-in-time’ approach, ensuring materials arrive precisely when needed, minimizing storage costs and the risk of obsolete stock.

- Over-processing: Adding features or quality levels beyond what the customer requires can result in wasted effort and resources. Lean emphasizes producing exactly what the customer needs, nothing more, nothing less.

- Motion: Excessive movement of people or machinery can lead to inefficiencies and even safety hazards. Lean focuses on designing workspaces for ergonomic efficiency minimizing unnecessary motion.

- Waiting: Idle time, whether for materials, equipment, or information, can significantly slow down processes. Lean seeks to eliminate these bottlenecks, ensuring a smooth and continuous workflow.

- Transportation: Unnecessary movement of materials can lead to increased lead times and potential damage. Lean aims to optimize transportation routes, ensuring goods flow seamlessly from one point to another.

- Unused talent: In today’s rapidly evolving business landscape, tapping into the full potential of your workforce is essential. Failing to leverage employees’ diverse skills, experiences, and insights can lead to missed opportunities for innovation and process improvement. Lean recognizes that every team member brings unique talents and perspectives to the table. Empowering employees to contribute their full range of skills enhances individual job satisfaction and drives overall organizational success.

Don’t Forget about the People

By acknowledging “Unused Talent” as the eighth waste, organizations can unlock a wealth of untapped potential within their teams. This shift in perspective transforms the workplace from a collection of job roles to a dynamic ecosystem of creativity and problem-solving.

Remember, Lean isn’t just about optimizing processes; it’s about maximizing each individual’s value to the organization. When employees are empowered to unleash their full potential, the results will be nothing short of transformative.

Organizations can substantially improve efficiency, cost-effectiveness, and customer satisfaction by recognizing and addressing these eight types of waste. Embracing Lean Six Sigma principles is not just a methodology, but a mindset that paves the way for sustainable success in today’s competitive landscape.

How have you eliminated Lean Wastes from your processes?

Stay tuned for our upcoming posts around Lean Six Sigma and our newest Lean Six Sigma Course offerings.

Follow Lauren Hisey on LinkedIn and YouTube

Leave a Reply