Results with a toolbox

- Reduce non-value add

- Reduce Waste

- Reduce variation

- Increase quality

- Reduce cycle-time

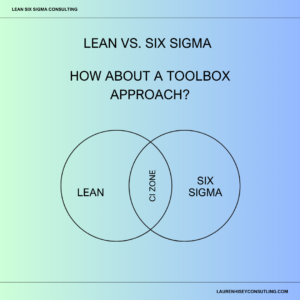

Lean vs. Six Sigma: How about a Toolbox Approach?

At the heart of process improvement lie two robust methodologies: Lean and Six Sigma. These approaches have been widely adopted across industries, each with its tools and principles. R centlDuringerence, I engaged in a thought-provoking conversation about the merits of Lean versus Six Sigma. We spoke in great detail about how one approach was used versus the other. I was first taught Six Sigma in my career, but Lean was soon added to my training. I’ve always felt that a Toolbox Approach was more critical than one methodology. Let’s explore methods and understand how they can work together to create a robust toolkit for process excellence.

Understanding Lean Six Sigma

Lean Methodology

Inspired by Toyota’s production system, Lean focuses on eliminating waste and streamlining processes. Its core principles include:

- Gemba Walk: Going to the place where the process occurs to learn firsthand from the people who work it.

- Value Stream Mapping: Identifying value-added and non-value-added steps in a process.

- Kaizen Events: Continuous improvement through small, incremental changes.

- 5S: A method for workplace organization (Sort, Set in order, Shine, Standardize, Sustain, Safety).

Six Sigma Methodology

Six Sigma, rooted in statistical analysis, aims to reduce process variation and defects. Key components include:

- Statistical Process Control (SPC): Monitoring and controlling process performance.

- Analyzing and optimizing with statistics: Analyzing and optimizing processes with statistics to help drive data-driven decisions

- DMAIC and DMADV: Structured problem-solving methodologies (Define, Measure, Analyze, Improve, Control; Define, Measure, Analyze, Design, Verify).

Both Lean and Six Sigma share a common goal: improving processes to enhance efficiency, quality, employee satisfaction, and customer satisfaction.

The Toolbox Approach: Combining Lean and Six Sigma

Why choose one when you can have both?

Rather than pitting Lean against Six Sigma, consider adopting a Lean Six Sigma approach. Here’s why:

- Here’s the View: Lean provides a broad perspective, touching every facet of a business. I encourage oration and cultural change.

- Precision and Rigor: Six Sigma monitors the supply chain, identifies defects, and applies statistical rigor.

By combining these methodologies, organizations can simultaneously address waste reduction, process efficiency, and quality. I feel that using just one methodology will only get you halfway to Continuous Improvement.

Leveraging the Best of Both Worlds

Each method has specific tools, but combining them opens a new door to how to approach things. There are many different ways to use the tools together. Let’s delve into specific tools that you can use:

!. DMAIC: Using the DMAIC problem-solving method, regardless of how big or small another project is, provides a systemic approach that can be used to help guide you.

2. Process Mapping: While there are different kinds of maps, I wanted to group this one to talk about some of the types of maps that I often use with my clients. I always include a SIPOC, VSM, and detailed process mapping. The SIPOC and the VSM provide a 10,000-foot view, but the main difference is that the VSM provides the end-to-end process flow while the SIPOC provides that view for a specific part of the VSM. The detailed process map gets you to the 5-foot view to see what is really going on the ground.

3. Kaizen events: Rapid improvement workshops with cross-functional teams that usually take 2-5 days to redesign the processes in different parts of the workstreams.

4. Statistical Process Control: Using control charts to measure before, during, and after projects. Control charts play a huge part in Visual management to ensure that processes are operating optimally after improvements are made and can help provide guidance when issues come up. If you can control a process, you can control the outcomes.

This is just snap shot of the tools that you can use. Remember that the toolbox approach allows you to pick the right tool for the right situation.

When to use Lean vs. Lean Six Sigma

There are times when one methodology is better than the other, but I break it down in different ways than most:

- Lean: Ideal for lightweight, continuous improvement in innovation, service, and administrative processes. I is a good idea to have all of you employees understand Lean and how they can improve things daily. is providing empowerment to let your employee make changes at their level so the entire company can become Lean.

- Lean Six Sigma: Suited for reducing waste and non-value-added holsticks while also reducing variability within complex situations and overall end-to-end processes.

Conclusion

Lean and Six Sigma are not adversaries; they are allies. Embrace the toolbox approach, adapt it to your unique context, and empower your organization to thrive. Remember, it’s not about choosing sides—it’s about choosing results

Ready to learn how to apply Lean Six Sigma to your organization?

We offer Lean Six Sigma consulting and coaching. Let t’s set up some to talk further.

Follow us on LinkedIn.

Leave a Reply